API Standards for Drill Pipe Inspections

With so many innovative tools found on a drilling rig today, it’s easy to overlook the role of the drill pipe. That is, until it fails during operation. Fortunately, this is not a common occurrence due to regular drill pipe inspections. Drill pipe inspections are imperative to ensuring the drill pipe remains reliable and safe to use in operation. The inspection identifies when pipe or other drill stem elements must be repaired, reinforced or retired due to integrity issues.

What happens during a drill pipe inspection? How often are they conducted? The industry best practices are contained in API RP 7G-2: Recommended Practice for Inspection and Classification of used Drill Stem Elements. This API standard describes the requirements for each level of inspection and procedures for the inspection and testing of used drill stem elements.

By following the API Recommended Practice, inspectors and operators can rest assured they are maintaining high-quality drill pipe and won’t experience non-productive time (NPT) due to drill pipe issues. All of Turnco’s processes and services have these standards baked in; so customers know when they choose Turnco, they are choosing the highest standards in the industry. Let’s take a look.

Quality Assurance in Drill Pipe Inspections with D90

One of the first sections of API 7G-2 requires a written quality management program that details inspection procedures and documentation. Turnco has a rigorous quality management plan that incorporates the recommendations of all related API standards and goes above and beyond when it comes to documentation and data sharing – it is called D90.

Turnco’s D90 process not only includes API best practices but also incorporates the operators own SOP, so only approved parts can be ordered. The D90 process combines big data, drilling analytics, quality assurance, and real-time cradle to grave tool data to optimize drilling quality.

Want more info on the D90 process? Read our D90 blog to see the platform’s full capability.

Read the D90 Blog

How is drill pipe inspected?

API RP 7G-2 walks through the inspection of the following elements:

- Drill pipe (body)

- Tool joints

- BHA connections

- Drill collars

- Subs

- HWDP

- Kellys

- Stabilizers

- Jars

- MWD/LWD

- Motors/turbines

- Reamers/scrapers

- Rotary steerable

- Proprietary tools

The type of nondestructive testing (NDT) to use on each component is detailed, as well as what measurements are taken.

Nondestructive Testing in Pipe Inspections

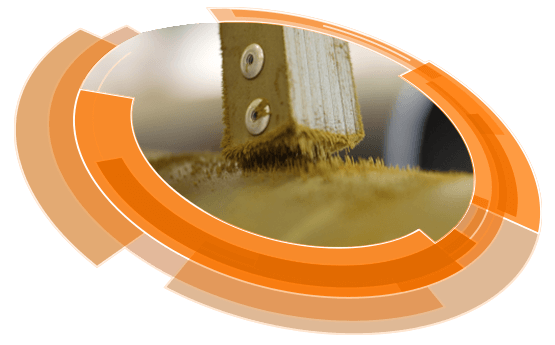

How is the pipe inspected? Various methods of nondestructive testing are required. Some inspections can be done in the field between wells or trips (such as visual inspections and pipe length measurement), while others use specialized equipment and are conducted after the pipe is sent from the field. NDT methods referenced in the API standard include:

- Magnetic particle inspection

- Ultrasonic scanning

- Electromagnetic inspection (EMI)

- Liquid penetrant inspection

- Wet magnetic particle inspection

- Visual Inspection

These methods take many different measurements of the drill stem elements. They can detect changes in the metal and even determine the cause of the change based on how the drill pipe has warped.

Outside diameter (OD) gauging and wall thickness are two important measurements obtained through NDT. The OD erodes during normal use of the drill pipe from drilling to new depths and tripping in and out of the hole. The drill pipe may erode from the inside as well. Higher pressures and temperatures can accelerate wear. That leads us to drill pipe classification.

Drill Pipe Classification

Drill pipe is classified based on how much erosion has taken place. The thickness of the drill pipe wall becomes thinner, and eventually, holes will appear in the drill pipe wall if nothing is done to repair or reinforce the metal (such as hardbanding). Operators use the classification to determine whether that drill pipe is safe to use in a certain operation. Some projects may dictate that only premium pipe may be used while others can get by with class 2 or class 3 because the drilling environment is not as demanding.

- New: Brand new pipe that’s never been used. Drill pipe can only have this classification once, and that’s before it ever hits the field. Once it goes downhole, even if minimal wear takes place, it can no longer have “new” classification.

- Premium: The remaining wall shall not be less than 80% of the new specified wall.

- Class 2: The remaining wall shall not be less than 70% of the new specified wall.

- Class 3:The wall thickness is less than the minimum for class 2

See Table B.18 – Classification of Used Drill Pipe for more in-depth classification detailing how to classify pipe with other types of wear issues.

What issues can be detected with a visual inspection?

Each component of the drill stem requires a visual inspection along with the other recommend NDT tests. These issues can be caught by the naked eye. Inspectors can easily identify these issues, but rig hands should be on the lookout for easy-to-catch issues in the drill pipe and tool joints.

- Galled threads or pulled threads

- Crack indications in pipe, threads and box connections

- Galled seals

- Seal damage to shoulders

- Pitting, corrosion, dents, mashes

- Indications of washout on connections

- Increased wear in slip area of the pipe body

Inspection levels

Depending on the operating environment and the operating experience, the operator can work together with the inspection company to determine what level of inspection is appropriate for the project at hand. Higher costs are associated with higher inspection levels. The details are found in Annex E of the API standard.

- Standard – Low project risk and low operating life

- Moderate – Medium project risk and standard operating life

- Critical – High project risk and long operating life

- Extreme – Very high project risk and very long operating life

Other API standards exist to specify the delivery specs for drill pipe manufacture. Check out these API documents to know what the drill stem elements should look like when they’re new:

- API Spec 7-1: Specification for rotary drill stem elements

- API RP 7-2: Specification for threading and gauging of rotary shouldered thread connections

- API Spec 5B: Threading, gauging and inspection of casing, tubing, and line pipe threads

- API RP 5B1: Gauging and inspection of casing, tubing, and line pipe threads

D90 Process and Drill Pipe Inspections

In today’s operations, everything is reactionary. If a tool fails, an inspection follows. But the D90 process is proactive. It leverages historical data to help make predictive drilling decisions. By integrating performance data for specific regions and tools, you can optimize your drilling practices and reduce non-productive time.

The D90 process utilizes Turnco’s BRITE system to provide the most transparent and accessible database in the industry. Anyone with access can view inspection data immediately upon being entered into the system.

The Best Part? D90 opens the door to advanced drilling optimization, like machine learning, real-time drilling analytics, and neural networks.

See the power of D90 for yourself – schedule a D90 demo for a complete walkthrough.